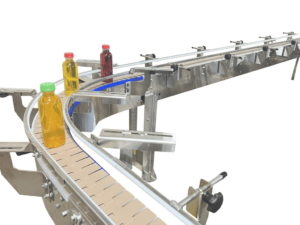

Dorner and Garvey are combining strengths to generate a new chapter collectively with the recent start of itsAquaGard GT Stainless Steel conveyor.This new line combines the very best conveyance expertise of equally brand names to produce a system with an interesting selling price stage that integrates with accumulation systems and other machinery to generate a entirely automated processing line for bottling, canning, and food items processing programs.

Dorner is a global chief in conveyor automation program style and design, manufacturing, and integration. Garvey is a identified innovator in the conveyor and accumulation business, serving buyers of all measurements principally in the foods, beverage, pharmaceutical and home product or service industries. Dorner and Garvey are two of 19 international makes of Columbus McKinnon, a worldwide supplier in smart motion alternatives for substance managing programs.

The AquaGard GT merges the strengths of Garveys GT Collection conveyor with Dorners AquaGard 7100 Series sanitary stainless metal conveyor. The AquaGard GT is a meticulously made infeed and outfeed conveyor ideal for accumulation-style apps to prevent bottlenecks in industries these as packaging, bottling, dry foodstuff processing, and element handling. All elements (other than motors) are both stainless metal or Fda-authorized plastics, which are great for functioning in environments that involve wipe-down or occasional washdown cleanings of the conveyor.

The AquaGard GT conveyor system is created to be as very simple as attainable, ensuring the best amount of trustworthiness. These conveyors are engineered for overall flexibility and can be inserted virtually everywhere in the system, generating line expansions or entire changeovers quickly and efficient. With Dorner’s very best sector direct time, conveyors can be personalized engineered and shipped out speedily to lessen downtime and get a manufacturing line up and functioning in no time.

The AquaGard GT conveyor is a adaptable alternative ideal for an array of programs throughout a broad assortment of industries. Mainly developed for packaged fantastic transport, its robust development and highly developed engineering assure seamless motion of products with precision and trustworthiness. Its adaptability shines in integrated remedies by navigating as a result of equipment for productive processing. Additionally, its seamless integration extends to end-of-line packaging and palletizers as perfectly in which it makes sure clean transitions and optimized throughput, boosting all round operational efficiency.

The AquaGard GT integrates features and advantages this kind of as run transfer models, flush aspect tails, and pre-engineered transfer modules, among the other folks that in-home machine builders are unable to match. The conveyor is competitively priced and will come with a shorter 10-working day guide time.

For extra facts, take a look at