Forklift operators who are insufficiently informed of the load they are lifting and the dangers that come with exceeding the forklift rated ability not only compromise their own security, but also area everyone working around them at major hazard.

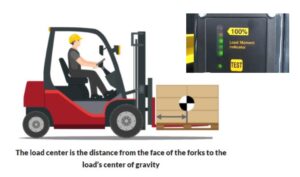

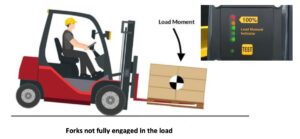

There are a number of components that can impact a forklift truck to develop into overloaded and these consist of: load centre, bodyweight of load, carry height and the kind of load. The load centre, which is the length from the face of fork to the centre of gravity of the load performs a critical part. The posture of the load centre can also vary relying on the kind of load remaining lifted, for case in point liquid loads or non-uniform hundreds.

Forklift operators should really be skilled in knowing the weight of the load. Combilift’s new merchandise, the Combi Protected-Raise, is an anti-overload machine which allows operators to avoid the pitfalls of opportunity overloading, which can have significant effects if it happens.

The Combi Harmless-Raise incorporates a pressure sensor on the mast part and a raise slash-out valve on the hydraulic line to disable lifting if the device is being potentially overloaded.

The Combi Harmless-Raise incorporates a pressure sensor on the mast part and a raise slash-out valve on the hydraulic line to disable lifting if the device is being potentially overloaded.

There is an audible alarm which warns the operator of an overload scenario, and a load minute indicator is equipped to the dashboard in the cab. The operator can immediately see from the green, amber and red “traffic light” signalling when there is a risk of overloading or when the forks are not absolutely engaged for example and acquire acceptable motion.

For extra information and facts, go to