Image courtesy of MAG

Take a holistic approach to safety with your AGVs and AMRs.

Contributor: MHI’s Mobile Automation Group (MAG)

Ask anyone considering mobile automation in the warehouse what their biggest concerns are, and they’ll likely mention safety as one of those concerns. Buyers are concerned about automated guided vehicles (AGVs) or autonomous mobile robots (AMRs) colliding with people, lift trucks, racks and more. Safe operations should be front and center, and the makers of mobile automation work hard to ensure that’s always the case.

“On the issue of vehicle safety, collisions could be a concern,” says David Emanuel, business development manager at Amerden AGVS. “That’s obviously the biggest way that mobile robots can hurt you.”

Customers’ safety considerations, however, are often related to the vehicles themselves and their accident-avoidance systems. “Many people only consider a vehicle’s sensors when they think about safety,” says Kai Beckhaus, president and CEO at Wagner Fire Safety. “But there are other aspects of safety to consider when it comes to these vehicles.”

Forming a more holistic approach to safety with mobile automation, including change management as a platform for safety — one that doesn’t rely entirely on the vehicles’ sensors — is key to covering all your bases. You should consider several other factors regarding the safe operations of mobile automation in your facility.

TAKING A 360 VIEW OF SAFETY

When it comes to a holistic approach to mobile automation safety, remember it’s a collaborative effort, says Emanuel. “When we install an AGV system in a warehouse, we remember that they’re potentially the most hazardous system there, so we provide a good deal of training to personnel,” he says. “We make sure there is plenty of signage, labeling in the areas where they travel, and even indicator lights if the customer is willing to spend the money on them.”

All suppliers will provide training on standard operating procedures, and all customers should emphasize this to their personnel from the start of the project, not only once mobile robots are running in their facility. However, it shouldn’t end there. Emanuel recommends that customers offer regular, updated training to their staff as time goes on so that safety remains front and center in their minds.

Another piece of that equation is ensuring formal processes are in place — not only should you train your staff, but you should document that and provide a manual for training. This can even extend to visitors who enter the building. “There shouldn’t be any gaps,” says Beckhaus. “It’s not rocket science, but it’s easy to overlook and forget important steps.”

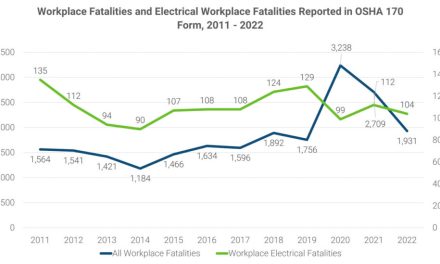

Beckhaus says environmental safety should also be considered after training. This extends to charging and pre-operation inspections. “Before you put your automation on the floor, do a visual inspection to look for any damage,” he recommends. Look for any dirt that might have accumulated, as that could lead to an electrostatic charge.”

At the charging station, ensure that workers follow the protocols. “Just as with EVs, you want fast charging, so the current will be high,” he says. “Make sure your staff is aware of electric hazards, and out of an abundance of caution, consider placing charging plates high up so that no one can accidentally step on them.”

REDUCING LITHIUM-ION BATTERY FIRE RISKS

Also, consider fire risks, especially when dealing with lithium-ion batteries. In these cases, it’s wise to lower the oxygen levels in a warehouse, says Beckhaus. “We introduce nitrogen to a sealed warehouse to bring those levels down to 15-16%” he explains. “Staff can still breathe comfortably, but then there isn’t enough oxygen to sustain a fire.”

When it comes to mobile automation, Emanuel ensures they are designed with safety in mind, something all qualified suppliers should do. “I make sure that there are escape routes on either side of the path they travel,” he explains. “That means 18 inches of clearance on either side. You might say that with sensors, why are they necessary, but it’s specified in ANSI/ITSDF B56.5 Safety Standards.”

AMRs can dynamically change travel paths, so your staff needs to be aware of that fact while in their midst. “In general, people are aware of mobile automation in their work areas, but a level of discipline is required if you’re going to keep everyone safe,” says Emanuel.

At the end of the day, it comes down to a holistic approach that crosses all the Ts and dots all the Is. “There will be aspects of mobile automation safety that people will overlook,” says Beckhaus, “and that’s why it’s good to review and remind people of them regularly. Safety is not a feature or benefit; it’s a mindset.” WMHS

MHI’s Mobile Automation Group (MAG) members are the industry’s leading suppliers of automatic guided vehicle systems. They supply systems worldwide and in virtually every major manufacturing and distribution sector. Learn more about MAG at www.mhi.org/mag.

The post Mobile Automation: Safety Beyond Sensors appeared first on Workplace Material Handling & Safety.